About

the Teega

Background

The Nasa Para Wing (NPW) kites are extremely popular and it’s

not hard to understand why.

First of all, they are cheap to buy and offer a cost-effective way into

many power kite sports.

Second, you can easily build one yourself and there are many plans

available on the internet.

Third, they pack down small and weigh very little so it’s easy to

always have one with you.

Fourth, the time required for setting up to fly is minimal – a minute

or two is enough!

Fifth, they are easy to launch, land and relaunch without assistance,

regardless of size.

Sixth, they have a massive pull relative to their size.

Seventh, they are virtually unbreakable (but please remember that you

are not!).

Eighth, because of their excellent low wind properties, they have a

wide wind range.

Advanced kiters, however, often complain about the performance of NPW’s

compared to that of the latest foil designs. And it’s true that NPW’s

have drawbacks. The main ones are these:

- The pull generated is very strong in the power zone (straight

downwind) but small at zenith and to the sides.

- The pull is uneven and hard to control, making the flyer constantly

work hard to get the power he or she needs.

- The flying window is smaller than it is with foils, LEI’s and hybrids.

- They can’t be water relaunched.

While I agree with the above, I believe the first two points can be

improved with a good NPW design. The flying window is a bit smaller,

partly because the NPW’s need a certain angle of attack to stay

inflated properly but also because they weigh so little that there is

no momentum in the kite that helps to expand its flying window when in

flight. But the great advantage of the ultra low weight is that they

fly in virtually no wind. So even if you prefer flying advanced

foils/LEI’s/hybrids, this aspect should make you want at

least one (preferably big) in your quiver of kites: It will fly when

all

other power kites refuse to leave the ground!

After more than a year of tuning various NPW9b profiles – I have over

40 well performing profiles from 2003 with explicit comments on my

computer – I started summarizing what I had learned so far. Some

parameters of the design are fairly fixed while others can be varied

and the possible combinations are seemingly endless. The more I studied

the data, however, the more I felt I had enough information to make a

qualified guess on how to make a better NPW.

The result was named the Teega, a kite that has some unique features:

• A wider single centre panel than any other NPW: 75%

of chord.

• A bigger nose than any other NPW: 35% more than the

common NPW9b profiles.

• A very clean sail shape for less drag, wind

separation and flutter.

• A profile with exceptional pull, speed and

stability.

• A slightly cupped trailing edge by tensioning of

the reinforcement cord.

• As easy to build as other NPW’s!

How does it

perform?

Let me begin by summarizing the two main NPW9b profiles that I

made during 2003:

The Buzzard One

profile was the first and I use it as a reference since it’s widely

spread (it’s the default profile in Jean-Pierre’s NPW9b calculator

and the profile that Tom “KiteMan”

White

currently uses in his downloadable building program). Its main

advantage

is that it pulls very evenly, regardless of flying direction, and is

very

smooth and controllable in its behaviour. The flying window is about

135°

sideways and is largely a compromise between good behaviour and big

window.

Pushing it another 5-10° is possible but results in the kite

becoming

nervous, twitchy and generally unpleasant.

The Buzzard Vnose

profile (which is available in J-P’s calculator download and can be

imported into the program) started with an idea of a different bridling

at the nose. The intention was to make the nose less distorted and more

stable against collapsing, but after some tuning it became evident that

this small change in bridling resulted in a kite that wanted an

entirely different bridling to perform

at its best. I decided to do it from the beginning again (it does go

faster

the second time, though ) and the result became a kite that is faster

and

has a slightly bigger window than the Buzzard One; at least 140°

sideways and an amazing ability to park very close to zenith. Improved

acceleration and the fact that it is flatter across its width (less

cupped) also gives it more “depower”; its flying speed determines the

pull to a higher degree than it does with the more constantly pulling

Buzzard One. The drawback

is that the Vnose profile overall pulls slightly less. A good idea is

therefore to increase the planned size about 10%.

The Teega is a different creature altogether. Its flying speed and

window is as good as the Vnose profile, but it responds quicker and

more precisely to the flyers input. The Teega has an incredibly strong

pull which is more evenly distributed across the flying window and

holds up better through tight turns. The sail also holds its inflated

shape better in sudden gusts than the flatter Buzzard Vnose.

The quick and precise response makes the Teega very well suited for big

sizes. In comparison, the Buzzard NPW9b’s feel slower in reaction, more

“floaty” and less powerful.

Now go ahead and make one! You will not regret it.

How do I fly it?

The Teega, along with all NPW’s, needs some tension on the brake lines

to keep it properly inflated. Eliminating this character in the design

of the kite is easy to do, but results in a kite that does not perform

at its best. Flying with some tension on the brakes is easy to learn.

How and when the collapse begins differs between various NPW models,

however. The Teega is easy to fly in this respect as it is very stable,

has a soft way of collapsing (by nose deformation rather than a violent

collapse with total loss of power) and never really does anything

unexpected.

To turn, you either pull in the brake on one side, which causes a sharp

turn. Alternatively, pull on the entire side (power and brake line) for

a more gentle turn. Doing one at the left side and the other at the

right

side causes it to fly sideways! Pulling in both brake lines makes it

fly

backwards. Like all NPW’s, it is preferably flown with handles, but big

ones can also be controlled with a bar (brake lines connected to bar

ends).

All four flying lines should be equally long.

The “depower” (not true depower because the angle of attack of an NPW

can’t be varied) of the Teega works as follows: Flying speed controls

the

amount of pull. Slowing the kite down by pulling in both brake lines

makes

it pull less. If you become seriously overpowered, pull hard on the

brakes

until the kite collapses and flutters around with very little pull,

rather

than putting yourself in danger. If that is not enough, let go of one

handle

to make it pull even less.

When the wind is strong, launch and land at an angle instead of

straight downwind to reduce the risk of getting overpowered. When

landing it can easily be backed down with the trailing edge first

(preferably to the side if the wind is strong) or simply flown into the

ground nose first. Nothing will

break. If it has landed on its nose, it can be restarted backwards by

pulling

on the brakes until it backs up.

The Teega can be flown on two lines instead of four, but there is

little to gain from this except that it’s easier to learn how to fly a

kite with two lines. What you loose is the ability to control speed, do

sharp turns, reverse starts, safety collapses and much more. I have so

far not provided the brake line lengths for a two-line setup. These

are, however, easily found by experimentation.

When packing away, the flying lines can simply be rolled up on the

handles, all the way up to the kite. When preparing to fly next time,

simply lay the kite on the ground and let the lines roll off the

handles while you walk

away from the kite. With a little practice, this can be done with zero

tangles and twists in the lines and the time required for packing up

and away is

reduced to a few minutes.

What size

should I choose?

If you have little or no flying experience with NPW type of kites, the

default size of 3.7 square meters is a good choice for your first

Teega. It is big enough to fly in very light wind and perfectly

manageable in moderate winds. Smaller sizes are faster and bigger ones

pull more, both of which

can be more demanding on the flyer. Remember that this kite is not

suitable

for children! Always fly with care – a modest 3.7 sqm NPW can get you

seriously injured or even killed in stronger winds!

How to

build your Teega

There are many ways to build NPW’s. My favourite assembly methods are

Jean-Pierre’s, as described on the building

pages of his site (although I do simplify a few steps). Read them

when

my explanations below are not enough! If you are interested in

alternative

building methods, check out J-P’s links

page.

The tips & tricks of Bill Painter and Tom White are interesting;

they

use faster methods like hot cutting and simplified sewing.

Below you will find my instructions on how to make a Teega, print them

out and follow carefully! You really need these instructions because

several details differ from the NPW9b.

It is recommended that you adjust the thread tension on your sewing

machine so that a seam through 4 layers of ripstop doesn’t wrinkle or

curl up the sail.

Getting the right

dimensions

Download J-P’s latest

NPW9b calculator (this program runs in Windows only) and import the

Teega profile.

Change

the value of A to the size you want, choose between cascade and

standard

bridling (see ‘Bridle your Teega’

for

advice), copy (Ctrl-C) the window, paste into another program (like

Word)

and print out this page. I refer to this page as the ‘calculator

printout’.

All the measurements you need are on this page, with the exception

of

bridle A1 and the extra line. These two are calculated manually

(see

‘T-lines and Extra line’ for

details).

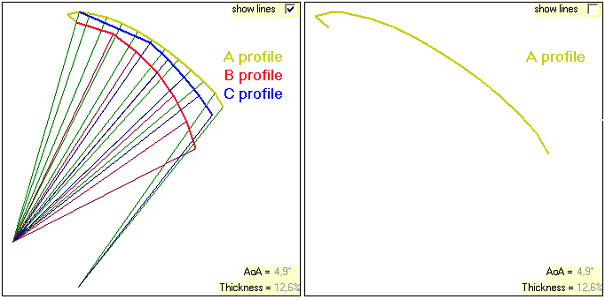

Please note, however, that the profile illustration shown in the

program is not entirely correct and neither is the AoA or Thickness

values. The reason it looks different on the screen is because the

Teega uses non-standard sail dimensions that the drawing part of the

program misinterprets. Remember that the numbers are all correct; the

error is only visual with no consequence to the builder! When designing

the Teega, I used a special version of the calculator - thanks, J-P!

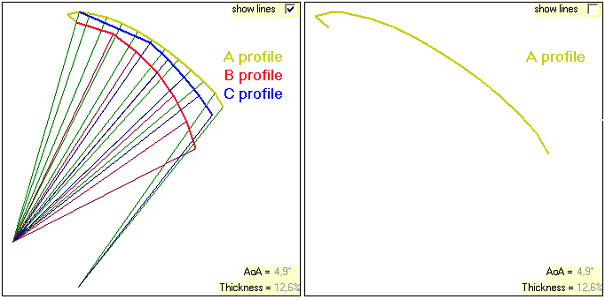

The actual profile, with brakes let out to full speed forward, looks

like this:

Cutting

and sewing the panels

Although many people recommend hot cutting, a regular cut with a knife

or a pair of scissors works fine with high quality ripstop like Chikara.

It is not necessary to cut and sew the nose part of the centre panel,

because there is very little stress in this area with the bridling

method

used on the Teega. The sail is therefore simply made of 3 rectangular

pieces,

all with the same height: A+4 cm. The +4cm is for the 2 cm edge

seam allowances. In between panels, 1.5 cm seam allowance is needed.

The width of the centre panel is B+3 cm.

The width of the ‘2 mid-wings panel’ is C+6.25 cm.

The width of the ‘2 edge-wings panel’ is G+7.25 cm.

What is easy to get slightly wrong is the diagonal cutting of the wing

panels. This is how you should measure at each end to get the correct

seam allowances:

Sew the 5 panels together using the ‘stitch with

reinforcement cord’ as described by J-P. To make it easier to sew

near the nose where two seams meet, let the reinforcement line end at H

cm before the nose corner in all four seams (see illustration below).

Sew the perimeter of the leading edge and the nose, using the ‘rolled seam with

reinforcement cord’ technique as described by J-P. Personally I

find just one zigzag stitch is good enough here. In the next

illustration, the thick black lines show where you have sewn so far. Do

not yet sew the trailing edge!

Now take a piece of bridle line (or any other line with little

stretch) that is a bit longer than the height A of your kite. With the

sail laid

out perfectly flat on the floor, have a helper hold one end of the line

at the left corner of the nose. If you are working alone, you can tie

the

line around the leg of a heavy chair and then put the corner of the

nose

under it.

Take a pen and wind the line around it a few turns so that it is

secured with the tip of the pen at the outer wing corner. With the pen,

draw a curve from the wing corner to the centre panel and cut this

piece off with a pair of scissors. There should be nothing removed from

the centre panel or the wing corner, only in between these two points!

(If these points are not on equal distance, you will have to remove

some fabric from the panel which is longer, so that A=E=F). Do the same

thing with the right side of the kite.

The following illustration shows you where to draw and cut:

One way of making sure the kite is perfectly symmetrical is to fold it

double and copy the left, already cut, wing to the right side.

Tensioning

the trailing edge

In this step you will sew the entire trailing edge, double

folded, with a straight stitch and a reinforcement cord lying freely

inside it. Make sure that the height of the kite becomes exactly A cm

when you are done. Also remember to roll the seam to the same side as

you did

before, so that all folds end up on the same side.

Starting from the left, sew the trailing edge from the left corner to

the centre panel. The reinforcement cord should stick out at both ends

but

must be secured by a few stitches in the middle (where mid-wing and

edge

panels meet). The X in the next illustration indicates where the line

is

secured:

Cut the cord and continue with the centre panel: Secure the end of a

new cord (where X is in the illustration below), sew the trailing edge

of the centre panel and let the cord stick out where the centre panel

ends:

Begin with a new cord and sew all the way to the right corner, with the

cord sticking out at both ends. Secure the cord at the middle (X in the

next illustration) as you did on the left side. The entire trailing

edge

is now sewn.

Each of the five panels can now be tensioned by pulling on the free

cord ends. This is done by laying the sail out perfectly flat, securing

the sail at the point where the cord you are about to pull is fixed (at

the X) and very gently pull on the loose end. Just before the sail

starts to wrinkle or bend, put a mark where the cord exits from the

seam. This mark represents zero tension in that panel. Then

pull out the right length (as specified below) and secure the cord with

a few stitches or put a knot on the end so it can’t slip back in.

The shortening to make for Teega

version 1.1 is: 0.04*B cm on the centre panel and 0.015*A cm on

each

of the other four panels.

Measure the centre panel width B at the nose of your finished sail,

from reinforcement line-in-seam to reinforcement line-in-seam. If B

differs from what the calculator printout says, recalculate L=B/6

before drawing the darts in the next step.

The Teega nose

Carefully draw the 5 nose darts, equally spaced with L cm between each

tip, on the front of the sail. The front is the side that has the edge

folds on it and will be facing the flyer when in the air. Note that the

Teega uses no side darts! Their width is specified as 0.01 cm, because

the

calculator does not accept zero.

When drawing the nose darts, please make sure that each dart has the

exact width K at the very edge of the sail. This is important for the

final shape of the nose and the flying performance. When the darts have

later been sewn, the nose ”edge” should be exactly 5*K shorter than the

”base” of the nose.

Also draw a line where the nose reinforcement line will be sewn. It

runs in a straight line between the tips of the darts (at H cm from the

nose edge) and then makes a gently rounded curve at each side, from the

last dart tip to a point M cm from the nose corner. See the following

diagram (and also the photo below on the page):

Sew the nose reinforcement line with a straight stitch on the front of

the sail, right on the line you just drew. A flat piece of Dacron is

easiest to sew, but I usually manage with an 80 kg round Dacron line as

well (same as I use in the seams).

Fold each nose dart in the middle, along its central line, and sew with

a straight stitch as shown in the next illustration. Make sure you fold

them so that the front of the sail is facing out! Note that by not following

the triangle line exactly, but instead making the dart slightly bigger

in the base and slightly thinner and more ”pointy” towards its tip,

there is less distortion of the sail when it’s shaped to a 180°

round nose. The drawn straight line should be crossed in the middle.

It’s a good idea to draw the S-shaped line before sewing to make things

easier.

When all 5 nose darts are sewn, fold them against the sail and secure

them at their corners only with a few stitches or a drop

of superglue (cyano acrylate glue).

The following picture shows the underside of the first prototype Teega

with darts and reinforcement line sewn. The T-lines (2 showing) and the

Extra

line have been tied (as described in the next step). You can also see

bridles

A1 (tied to the Extra line), A2 (tied to the sail between orange centre

and

red mid-wing panel) and B1 (at the right bottom corner).

T-lines and

Extra line

The Teega profile requires the use of a ”Vnose arrangement” at each end

of bridle A1.

This is done by

1. Shortening both bridles A1 by T*1.5. Please do

this right away so you don’t forget it: Calculate A1-T*1.5, cross out

the value in box A1 on your calculator printout and write the new value

beside it.

2. Adding two Extra lines, one in each corner of the

nose, with the length T*3.3.

Tie the Extra line with one end in the nose corner and the other at M

cm towards point B1, right where the sewn reinforcement line ends. Fold

it in half and stretch out to measure that it has the right length.

Bridle A1 will later be tied around the Extra line with a bridle knot.

This knot should be able to slide on the Extra line so that A1

can find its optimal

position by itself. Do not worry if the knot later becomes very tight -

the

sliding is only needed for the first flight.

Tie the 5 T-lines, one at each nose dart, with one end around the

reinforcement line and the other end around the edge of the nose, at

the fold of the dart. All T-lines should have the length T, carefully

measured from the sail beneath the reinforcement line to the nose edge.

Note that on the Teega there are no T-lines in the nose corners, only

one at each dart. T-lines, Extra line and A1 are all tied with the bridle

knot shown under ‘Knots’.

Bridling your

Teega

Mark out all bridle attachment points, using the A-A, B-B and

C-C spacing values from your calculator printout. Always measure each

point

all the way from the trailing edge of the kite, to avoid small errors

accumulating. Please note that the top bridle points end up at

different distances from the nose (A2 is close, B1 a bit further down

and C1 is far away) – this

is how it should be!

Choose one of two bridling methods:

Standard bridling (non-cascaded) is a bit faster to make

and easier to get right. It is the preferred method on really small

kites (less than 2.5 square meters), as the measuring errors of a

cascade bridling can accumulate and degrade the performance.

Cascade bridling requires more tying of knots and

attention to bridle lengths, but it uses less line and will therefore

have less drag. The shorter bridles are also easier to measure

manually. Make sure your primaries are correct and you won’t ever have

to check them in the future. Secondaries can always be adjusted at the

sail.

Note that when you bunch and tie the lines together at the Q-point,

they get at least 1 cm shorter (depending on the thickness of your

lines) – this cm goes into the knot.

Since the Teega uses 3 brake lines (A11, A12 and C5), you have to let

one of the primary brake lines run all the way to point C5 while the

other

goes to the secondary pair A11-A12 when doing cascaded bridling.

See diagram below.

With standard bridling, you can run A11-A12 as a pair to the

Q-point and C5 as a separate line that goes through the Q-point knot,

ending with a stop knot. Always secure the Q-point knots with a few

drops of superglue.

I do the cascaded bridling (the bridling method I prefer) in

this order – it may not be the fastest way, but it works well:

1. I cut and tie all the secondaries to the sail, one pair at a time,

using the bridle knot shown under ‘Knots’. Each secondary has been

marked

at the midpoint (where the primary will be attached) and at its correct

length. About 5 cm extra is needed at each end for tying it to the sail.

2. I cut all primaries (double folded) and bunch them together at the

middle in four groups; 2 power and 2 brakes. They are marked at their

midpoint and at the right length +1 cm (that cm is for the loss in the

Q-point knot). All primaries are the same length (except the one that

goes all the way to C5), so this step goes much faster. Only about 2 cm

extra is needed at each end for tying it to the secondaries

3. I cut four 20 cm pieces of thick Dacron (at least 80 kg) – these

will become the Q-lines.

4. I tie each bunch of primaries at the midpoint with the Dacron line,

which gets folded in two. See knot 2A under ‘Knots’.

5. I make a stop knot on the end of the double folded Dacron and melt

the loose ends to a ball shape with a lighter so the knot can’t slip.

The

Q-lines are now finished!

6. I hang all four Q-lines from a hook in the ceiling.

7. I make a simple stop knot at each primary bridle (except brake C5),

at 0.5 cm after the marked primary length distance from the Q-point

(about that much disappears into the primary-secondary knot). The stop

knot is needed to keep the primary-secondary knot from slipping when

under load.

8. I place the kite with its secondary bridles on the floor and tie

each primary end to the midpoint of a secondary pair, making sure the

primaries are running straight all the way from the Q-point knot

without being tangled. See knot 2B under ‘Knots’. Last of all, I tie

brake C5 to the sail – note that its length from Q-point to the sail is

the sum of primary length and the value in box C5 (if

you click on ‘standard bridling’ in J-P’s calculator, the right length

will appear in box C5)!

9. Now that everything is in place, I fine-tune the length of the

primaries by pulling on the shortest ones until all primaries become

equally long. Then I pull hard on all primaries at the same time to

make the Q-point knot tight.

10. I put a few drops of glue on each of the four Q-point knots. This

is to prevent the primaries from slipping when under load. A drawback

with this is that they can’t be replaced one by one, but so far none of

my primaries have broken.

11. Done! After a few hours of flying, the secondaries can be measured

and re-tuned if necessary. The primaries will not need any adjustment.

Knots

1. I use the bridle knot shown below for attaching all bridles to the

sail (with a needle through all layers of fabric on one side of the

reinforcement line and back again on the other side of the

reinforcement line). It is also used for tying the T-lines, the Extra

line and for attaching A1 to the Extra line. A ”hot tool” for burning

small holes in the sail (as described by J-P) is nice but not necessary

in my experience.

Remember to tighten this knot by pulling on the right end. If you

incorrectly tighten it by pulling on the loose end, the knot will look

different and might “twist back” under load, resulting in the bridle

getting longer than what you adjusted it to. To adjust the length of a

bridle, pull on the loose end and the knot will slide up. It can then

be opened up with your nails and

adjusted without completely untying it.

2A. This knot is for attaching bridles to the Q-lines.

The black line is the bunch of bridles and the blue is the Q-line,

complete with a knot at the end (this is where your flying lines will

attach with a larks head knot). Start by gathering all the bridle lines

and then make a twist in them. Then tie the Q-line around them as

shown. Tighten well and

secure the knot with a drop of glue after you have made sure that all

bridles

have the correct length.

2B. The very same knot is what I use when tying

primaries to secondaries on a cascaded bridle. In this case, the black

line is the secondary bridle pair and the blue line is the primary. On

the end of the primary, you need to put a stop knot or it will slip! I

prefer not to glue this knot so that the secondary pair can easily be

replaced if necessary. I have broken secondaries, but only by crashing

into trees and getting the lines cut by sharp rocks.

Building

materials

Fabric

The Teega has been tested mainly on fabric of Chikara nylon ripstop.

This is a high quality material with a little stretch, but not the

cheapest to be found. Experiments have shown that stretchier, stiffer

or more porous fabrics perform worse and often require a re-tuning of

various bridle lengths.

There are many other ripstops to be found, most of them of lower

quality than Chikara. One that I have not been satisfied with is nylon

Shikarex. It is cheaper but similar to Chikara except for its much

stiffer coating. This stiffness results in flutter and more distortion

of the nose.

Bridles

The Teega prototypes have all used bridles of Dyneema/Spectra; 25-50 kg

for primaries and 15-30 kg for secondaries (the higher numbers are for

bigger kites). These are thin low-stretch lines and the best to be

found. Dacron is cheaper but stretches more – it will most probably

work, but I can’t guarantee that the performance will be as good using

this material. Dacron is, however, far easier to untie and is therefore

a good choice for secondary bridles

(using cascade bridling) if you want to make repeated experiments with

different bridle lengths.

Reinforcement line

Dacron works great here. I have used 65 and 80 kg strength and have

never seen a reinforcement line damaged or broken.

Sewing thread

Always use synthetic thread. I use ‘extra strong polyester’ which has

never failed but is probably overkill and the sewing machine needs to

be

carefully adjusted to be able to pull it through.

Flying lines

Use only Dyneema/Spectra flying lines. 30m is a very nice length for

most kites. Really big ones in smooth wind can benefit from longer and

really small ones in gusty conditions can benefit from shorter.

There are many recommendations about flying line strength on the net.

Mine (as well as Peter Lynn’s) is to relate to your body weight,

regardless

of kite size. For main lines, use 2 times your body weight. For brake

lines, use your body weight. For really heavy use one can increase this

to 3 times body weight for main lines and 1.5 times for brake lines.

Do’s and

don’ts

Do stick to Chikara nylon ripstop and bridles of dyneema/spectra if you

want your Teega to perform at its best.

Do try to be exact when measuring the following: The 5 darts and their

T-lines, the Extra line, bridles A1, B1-B6 and the brake lines. These

are most critical to the performance of the Teega.

Do sew the perimeter (edge) of the sail before making the darts. This

will make your dart measurements more exact and allow you to re-sew

them

if they are not.

Do remember that a regular knot is a lot easier to untie and adjust

than a nicer looking loop-through-centre-of-the-core attachment. The

short loose ends aren’t really visible when flying.

Do experiment with the Teega profile if you feel like it, but keep in

mind that its default values are thoroughly tested and should perform

well

without any adjustments.

Do contact me if you’re having problems: lejonklou@hotmail.com

I’d also very much appreciate a short email or a picture when you’ve

successfully built one!

Don’t use ‘Q-point extensions’ as they will alter the shape of the kite.

Don’t hot cut and discard the darts as it becomes impossible to alter

their shape afterwards.

Don’t try to manually calculate the bridle attachment points by

dividing the height of the sail with the number of bridles in that row.

Always use the spacing values from J-P’s calculator and mark out the

points by measuring each point all the way from the trailing edge.

Advanced

options

Centre panel width

Experiment with the NPW9b in 2003 showed that a wider centre panel

(B=A*2/3) had more wing properties and less parachute properties than a

narrow centre panel (B=A/2). The result was a kite that was more fun to

fly and performed better in terms of power control. The Teega takes

this

one step further by increasing the centre panel width to B=A*3/4.

Some people still prefer a narrow centre panel for aesthetic reasons.

In case you feel that way or wish to experiment with even wider centre

panels, there is no reason why you shouldn’t build your Teega with the

centre panel width of your choice. Fact is that this change can be made

with little or no adjustment to the profile. My guess is that the Teega

will perform reasonably well with centre panel widths between B=A/2 and

B=A.

What is important to know is that the only sail measurement that needs

adjustment is L. Calculate it as L=(centre panel width)/6. The number

of darts, their width K and all other values remain unchanged!

If you do choose to build a Teega with an altered centre panel width,

I would be happy if you let me know, regardless of whether you need

help

adjusting it or it flies perfectly.

Contact me at: lejonklou@hotmail.com

Trailing edge tensioning

The tensioning of the trailing edge, created by the shortening of the

reinforcement line, contributes to the high quality power and stability

of the Teega. The amount of shortening is a good compromise determined

by flying in different conditions. Altering this value affects the

performance, so if you wish you can make it adjustable. Tightening it

further increases the power, but makes the kite slower and more prone

to stalling, which can limit its performance in light winds. Decreasing

the tension makes the Teega slightly faster at the expense of stability

and power.

If you decide to decrease the tension, start by reducing the shortening

of the reinforcement line to 50% of the default values to get an idea

of

what it does. The Teega will fly with no trailing edge tensioning, but

will

be twitchy and prone to nose collapse in gusty winds because of its low

angle of attack.

Adding different amounts of tension to the edge, mid-wing and centre

panels is of course possible for those wishing to experiment further.

It is, however, complicated to evaluate as you will have to keep

records on which setting did what in various wind conditions.

Thanks to

- Jean-Pierre Gleyzes – for his willingness to always add

yet another useful feature to his excellent NPW9b design tool: The Nasa

Para Wing 9b calculator. Also many thanks for his great NPW pages and,

of

course, for hosting these pages about the Teega!

- Bill “NPWBill” Painter, alias NPWBill – for designing the

NPW9b by using Francis Rogallo’s 9th model in the Nasa Para Wing

series.

This was before the similarly looking commercial NPW9 was released and

the

‘b’ in the name was later added by Bill to avoid confusion.

- Tom “KiteMan” White – for spreading the NPW9b kite to

enthusiast around the globe with his excellent step-by-step building

program and for his clever tips on how to build NPW’s.

- Terence Kearey – for putting me on the right track when

designing wing profiles with his explanations of laminar separation

bubbles

and what causes them. Also for his in-flight videos of the NPW9b

Buzzard

Vnose that made it possible to study the differences between

theoretical

profiles and how they actually look in flight.

- Fred Cramer – for putting me straight on the not-straight

sewing method of the nose darts.

- Jan Claes – for his endless experiments with new NPW

ideas; triple centre panel, high aspect, different bridling,

progressive brakes, you name it!

- Larry Green – for his early experiments with the length

of the NPW9b T-lines, that inspired me to make the nose increasingly

fatter.

- Dave Culp – for bringing the benefits of tension along

the trailing edge to my attention.

- Francis Rogallo, the father of the Nasa Para Wing

parachutes, whose work pioneered the making of flexible flying wings.

- … and to everyone else at the discussion group

npw9b@topica.com!

|