BUILDING YOUR OWN FLEXIFOIL

10ft Flexifoil.

Power kites are the way of the future. An adrenalin rushing and

environmentally friendly sport. Using these kites you can propel yourself

through the sky or be dragged kicking and screaming (with a smile on your face)

accross the ground. Finally you can fulfill all those childhood dreams of

flight!.

Unfortunately power kites can be rather expensive to buy, so presented here

are the plans and instructions for building one yourself. From experience, the

home-made kite is more satisfying to fly, and allows you limitless room for

experimentation and choice of colours and sizes. The plans presented here will

build you a kite similar to the Flexifoil shown above.

I have now made four kites using this pattern, 1 X 1.8m in length, 2 X 2.4m,

and 1 X 3m. I have added these to the 1.8m Flexifoil that I bought. I would

recommend that you start by buying a flexifoil, and then as you hunger for more

power and experimentation you can start building your own. The bought flexifoil

serves as a guide as you build the first kite. When flown stacked (one above the

other), a light breeze is enough to get me jumping about and skidding

everywhere. To decide on the size of the kite you wish to build see size

notes.

What you will need:

- Spinnaker Nylon (Rip-Stop Nylon will do, Carrington

is better, and Icarex is divine. They do however increase in expense in that

order. The lighter and less air-permeable, the better.)

- Mesh (Fly-screen type netting will do however some

sort of Nylon gauze is much better - consult your local kite shop.) You will

need a strip as long as your kite and about 60mm wide.

- Dacron ~75mm wide strip, 30cm long.

- 2 rings 10-12mm in diameter. Aluminium ones are

great, otherwise plain washers will do. Make sure to round off all edges with

a small file.

- Nylon webbing - the type most backpack straps are

made of. 30cm length, 8-12mm wide.

- Polyester or Nylon sewing thread

- Flying lines - consult your local kite shop. High

breaking strength spectra recommended.

- Spars - These are a crucial component of these

kites. You can purchase the standard flexifoil spars (expensive) or be a

little more creative - more later.

- A sewing machine, coloured pencil for marking

pattern, sharp scissors, ruler.

- PATIENCE!

Note: When buying materials there are a number of

things to keep in mind.

- The lighter weight the materials, the better the

performance of your kite.

- Buy materials that will last a long time (e.g. cotton

sewing thread will rot after a while, synthetics are best.)

- Light coloured spinnaker nylon will make your sewing

easier when you are first starting out.

- The spinnaker nylon needs to be impermeable to air.

- It is probably a good idea to go to a kite shop and

study the types of materials used in this style of kite before beginning.

Study also the design of the kite as it will help you when you get to the

confusing bits of the construction.

Cutting the pattern

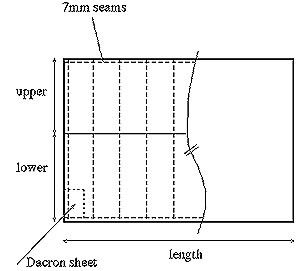

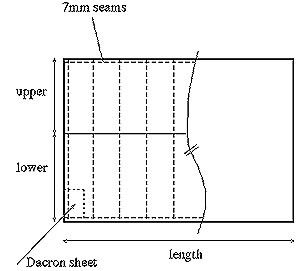

- Shown above is the pattern for cutting out the kite

material. There are three main components of this kite, the upper skin,

lower skin, and profiles. The upper and lower skin can be cut

from the one width of material as shown in the diagram.

- The pattern is symmetrical so only one half is shown here.

The dotted lines represent where you should pencil in the seam lines and the

profile guide lines. A contrasting coloured pencil to the colour of the

material is recommended.

- The number of profiles to put in depends on the length of

your kite. (See size notes)

- Once you have chosen the length of the kite and the number

of profiles draw them onto the material and cut it out. Remember to allow for

7mm seams on the sides of the upper and lower skins and on one side of each

skin.

Cutting the profiles

The profiles are calculated from the table below. Just

multiple each number by the chord length you have chosen then plot the upper

and lower distances perpendicular to a baseline marked with the corresponding

horizontal distances.

|

|

|

| Horizontal |

Upper |

Lower |

| 0.000xChord |

0.000xChord |

0.000xChord |

| 0.013 |

0.027 |

0.049 |

| 0.024 |

0.042 |

0.062 |

| 0.051 |

0.062 |

0.076 |

| 0.076 |

0.071 |

0.084 |

| 0.100 |

0.080 |

0.093 |

| 0.151 |

0.089 |

0.104 |

| 0.200 |

0.089 |

0.111 |

| 0.251 |

0.084 |

0.116 |

| 0.300 |

0.078 |

0.116 |

| 0.400 |

0.067 |

0.113 |

| 0.500 |

0.056 |

0.107 |

| 0.600 |

0.044 |

0.091 |

| 0.700 |

0.033 |

0.067 |

| 0.800 |

0.022 |

0.044 |

| 0.900 |

0.011 |

0.022 |

| 1.000 |

0.000 |

0.000 |

Two templates need to be

made for the profiles or airfoils that give the kite its body. These are best

made from a rigid cardboard or plastic sheet.

- The easiest way to do this is by drawing a baseline first

and marking a point on it as 0, or the front of the profile.

- After choosing a chord length (see size notes), plot the

baseline measurements according to the profile table given in the excel file

or or in the table above.

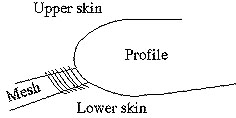

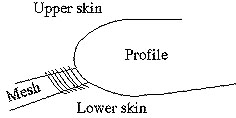

- Now plot the upper and lower measurements perpendicular to

the baseline measurements as shown in the diagram and calculated from the

profile table.

- Mark the Mesh / Upper skin transition on the template. It

is of utmost importance to do this accurately and to trace it accurately onto

each profile. The transition occurs at the first lower point.

- Once all the points are plotted join them using a

flexicurve or a french curve.

- This marks the first template which can now be cut out.

- The second template is made by tracing around the first

and then allowing for a 7mm seam line around that. (ie. 7mm bigger around all

sides)

- Now trace the larger template onto your material with the

smaller template traced inside it.

- Cut out the required number of templates. (see size notes)

Sewing

Hopefully you have not given up in frustration at these

instructions yet and you are now presented with a whole bundle of material and

are ready to sew.

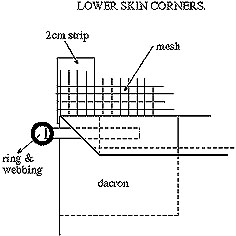

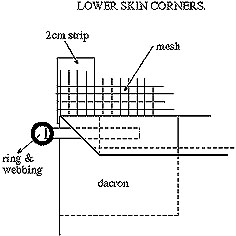

- Cut two pieces of Dacron, 75mm x 120 mm and sew them into

the corners at the leading edge of the lower skin. These points take the

highest loads of the kite therefore stitch them strongly.

- Cut your mesh into a strip as long as your kite and 50mm

wide. Draw two lines down the centre of your mesh strip, such that they are

15mm apart if your chord length is 450mm, and 24mm apart if your chord length

is 600mm+. For intermediate chord lengths, change this width proportionately.

- Stitch the mesh along the 37mm line on the lower skin on

the same side as the Dacron. One of the lines on your mesh should correspond

to the 37mm line. Stitch again a little further back from this line to prevent

fraying of the mesh at a later date. At either end of the mesh stitch a 25mm

wide piece of kite material, as long as the mesh is wide. This can be seen in

the figure below.

- You are trying to make a tunnel for the spar to go

through. Before stitching it up finish the corners as in the above

picture:

- Cut two 150 lengths of nylon webbing and thread a ring

over each one. Fold them in half so that the ring is at one end.

- Fold over the corner of the lower skin at a 45 degree

angle that intersects the 37mm line.

- Stitch the nylon webbing underneath this fold so it will

end up on the inside of the tunnel. Reinforce this with multiple stitches as

the webbing will take the highest load in the kite.

- Fold the 7mm seam line under and stitch down the 37mm line

to the 67mm line creating a tunnel along the full length of the kite. Make

sure you have finished both corners first.

- Once again reinforce the finishings at the beginning and

end of this tunnel with multiple stitches back and forth for this is where the

highest loads are expected.

- You can now stitch the upper skin of the kite to the mesh

such that the 7mm seam lin coincides with the second of the lines you have

drawn on the mesh.

Congratulations. You are now ready for the hard part.

Stitching the profiles in.

- Stitch each of the profiles to the upper skin in turn.

Ensure that the mesh/skin mark is aligned exactly each time. Be careful to

ensure that the seams on the two end profiles are turned inwards.

- Make sure you stitch right to the edge of the tunnel and

into the Nylon of the tunnel 2-3mm. Reinforce this point, this will make the

kite last forever. DO NOT STITCH THE TUNNEL CLOSED.

Easy huh?...Now stitch the profiles to the bottom

skin.

- Starting at one end of the kite stitch the profiles to the

bottom skin. Once again, do not stitch the tunnel closed however reinforce the

stitching at the closest point to the tunnel where your stitching begins.

- Always start from the tunnel edge and work your way to the

back of the kite.

- You should get something that looks vaguely like this

picture:

Now for the really tough bit...

- You are now ready to stitch in the last cell. This may

seam (excuse the spelling pun) a little impossible. It is not. Work your way

slowly along and stuff the bulk of your kite inside the last cell as is

required as you move along. You will eventually have sewed it inside out and

all you then have to do is pull the remainder of your kite out of the last

cell. This is a magical moment which generally occurs at 3a.m. in the morning

and you will feel a wonderful sense of achievement as it all turns out right.

- All you have to do now is stitch up the final seam along

the trailing edge of the kite. Trim any excesses from the back of the kite,

fold the seam over twice and stitch it down. this will give you and air tight

and strong seam. It is probably a good idea to stitch this seam twice for

extra strength. (Necessary for those unfortunate nose dives!)

- You have finished, go fly, go insane with joy!.

Spars

- As mentioned earlier you can purchase the standard

flexifoil spars for your kite. Beware, these are expensive.

- A cheap and satisfactory alternative I have found is

fishing rods. Most tackle shops have a collection of old rods or factory

seconds that they will be pleased to give to you or charge a small fee.

- Find two rods that are similar in stiffness and bend in

the same manner as the flexifoil rods you have previously looked at.

- It is now a simple job of removing those stupid guide

things that are bound on with cotton, cutting the rods to length, and joining

them in the middle.

- To join them the kind gentleman at the tackle shop may

give you a steel ferrule that fits. If not find an old piece of copper, steel,

or aluminium pipe that snuggly fits over the thick ends of your rods. You can

pack the ends with tape and epoxy if necessary.

- Alternatively you can use an old bolt with the head cut

off that fits snuggly inside the ends of these rods. Again tape may be used to

pack them.

- The disadvantage of these types of spars is that it can be

hard to find ones that are the appropriate stiffness and bend.

- The advantage is that they are much lighter than the

Flexifoil numbers and cost barely anything. My fastest kite, a modified

6footer, goes crazy with an ultra-light-weight set of fishing rods.

- The other alternative that I have been successful with is

buying normal hollow glass fibre spars and reinforcing them with carbon fibre

and epoxy. You will probably only find this possible if you have access to

carbon fibre. Simply wind it thickest at those parts of the rod you want

stiffest and remember that strips layed along the length of the rod will have

the greatest stiffening effect.

Size notes

Before building your

kite you will need to determine what size you would like. It is important in

this case to consider a number of things:

- Spar length....If you are going to be using standard

flexifoil spars, then you are restricted to their lengths.

- If you make your own spars (eg. using fishing rods or

something similar) then you can use any size you like!

- The shorter the kite, the faster and more manouevourable

it will be.

- The longer the kite, the more powerful and slower it will

be.

- The wider the chord, the slower the kite will be however

it will have more lift.

- The narrower the chord, the faster the kite will be.

- Remember to consider the width of the fabric you are using

so that you do not waste too much material in off cuts. Choose a chord length

that will allow you to cut the kite from one width. (eg.450mm chord requires

1040mm wide material, 500mm chord: 1160mm wide, 560mm chord: 1280)

- I have found that for a super fast 1.8m (6ft) kite, a

450mm chord is great. For a fast and powerful 2.4m (8ft) kite, a 500mm chord

is super. For a 3m (10ft+) kite that will pull your arms out of their sockets,

a 560mm chord is insane!.

- The number of profiles required depends upon the length of

the kite and the distance between the profiles. A shorter distance between the

profiles means greater shape stability and perhaps speed. Less profiles with

greater distance between them means less sewing. For narrower chord lengths

(<500mm), a 100 to 120mm distance between profiles is ideal, for longer

chord lengths (>500mm), 120-150mm between profiles is recommended.

- It is easiest to choose a distance between profiles that

divides easily into the chosen kite length (eg. 15 cells (16 profiles) in a

1.8m kite at 120mm intervals or 20 cells (21 profiles in a 3m kite at 150mm

intervals.

Other seemingly important stuff

- If you do use fishing rods, the diameter might be larger

and you may need to allow for this by creating a larger tunnel.

- It is often helpful to put a different colour on the lower

skin than upper so you can help your beginner friends become accustomed to up

and down.

- You can get adventurous and stitch all sorts of different

colours into your kites (like the one seen at the top of the page) however I

wouldn't advise it until you have built one or two plain coloured ones first.

- It looks very nice to have different coloured profiles

from your skin colours.