The delta is a light wind kite, particularly suited to thermal cruising. It is relatively easy to construct and conveniently quick to assemble on the flying field.

Construction materials are ripstop nylon and round hardwood dowel. For a cheaper alternative polythene sheet or tyvek could be used. For a stronger, but more expensive alternative, carbon fibre tube could be used for the outer wing spars.

Make a full size paper pattern first (after you have decided on the surface design). Cut out the fabric allowing for a 5mm seam overlap where different colours or areas of ripstop need to be joined by sewing. The seams are folded and joined on the upper side of the kite wings.

To be professional you could use a 'hot knife' to cut the ripstop, but a sharp scalpel and metal ruler is adequate.

The outer side edges of the wings have wider hems. These can be used to make the long sleeves into which the outer spars are fitted. Alternatively I sew a length of ripstop nylon, folded over several times to 15mm wide, along the top of the entire outer side edge of the wings which makes a good sleeve for the spar. Note these spars are shorter than the outer wing edge, and should be in the positions indicated on the plan below.

The trailing edge of the kite has a simple folded hem. The two exposed edges of the keel are edged in a length of folded ripstop 10mm wide. (photograph 4).

A curved trailing edge on the main kite wings can make a more elegant alternative to the angled edge I have used.

Note (photographs 1 & 4) the way in which the aluminium ring is attached to the towing point on the keel.

Where the two wings are joined along the centre of the kite allow 24mm hem. This is sewn together to create a sleeve into which the spine is fitted, on the underside of the wings. Both ends of the spine sleeve are reinforced with short lengths of folded ripstop (photograph 5 shows the rear of the kite).

Leaving a short gap in spine and spar sleeves is a good idea, especially if you need to replace them due to breakage.

Round off the ends of all hardwood spars and spine with sandpaper.

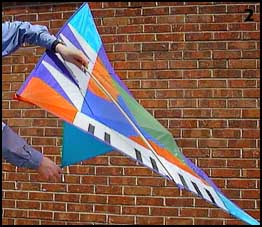

The delta is a semi-flexible kite. The cross spar connects to the outer edges of the wings, but is not rigidly fixed to the spine (photograph 2). This allows the wings to adapt freely to the wind. Fixing the cross spar to the edges of the wings can be done in a variety of ways. Photograph 3 illustrates the method I use, made from several layers of folded ripstop nylon. The length of the cross spar can be varied to suit differing wind conditions. A shorter cross spar allows the wings to form a steeper ' v ' shape (dihedral), which is more suitable for stronger winds.

Flying a delta kite:

A gentle breeze is all your delta kite needs for a good take-off. Avoid strong or blustery winds. Hilltops, open fields and beaches with a steady light wind are ideal for a delta kite. A powerful thermal will be enough to have your delta soaring to a great height like a glider.

Store your kite in a long ripstop protective sleeve. When you reach your launching spot carefully insert the cross spar into the wing pockets, and attach your flying line via a swivel clip to the towing point on the keel.

Stand with your back to the wind and hold the kite aloft to catch the wind, release and pay out line steadily until the kite reaches a stable altitude. Alternatively in very light winds try a long launch. Ask a friend to hold the kite at a distance of about forty metres, and as they release the kite, pull in line quickly. Pay out line to gain altitude as your kite begins to rise steadily.

For your safety do not fly near power lines, over a road, railway, near an airport or during a thunderstorm.