|

|

|

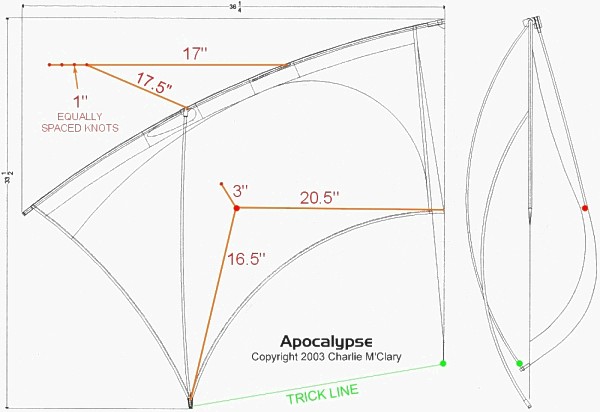

About the Apocalypse

These plans are published with

the permission of Charlie M’Clary to share his design with amateur

builders. Besides appearance, the

Apocalypse is an unusual kite for having a drum-tight sail, a central

stabilizing keel and no straight spars. The sail tension is increased by

the perimeter leech lines and bowed spars that keep the entire sail

tight and responsive. Unlike other quad line kites, a central keel

provides directional stability. To aid assembly, storage and

transportation, the LE spars disconnect from the nose fitting for

disassembly, keeping the spars with connectors and bridle knots intact.

Openings for the LE fittings and slots for the bridle allow limited

movement of the spars. A Dacron and Velcro flap retains the nose

fitting. The kite is 33.25 inches (850 cm) high and 79.5 inches (201.9

cm) wide, weighing 6.4 ounces (182 grams).Charlie says it doesn't dead-launch

easily, but he seems to like how it tricks on slack lines.

Materials

Icarex polyester fabric is probably the best fabric for this kite

as stretchy would make adjustments a never-ending task. 3.9-ounce

Dacron reinforcements are sewn at stress points along the leading edge

inside the spar tunnels. The leading edge spars are wrapped, tapered

carbon with remaining spars standard carbon tubes and rod. A short

section of plain carbon spar is glued into the small ends of the LE

spars to accommodate the small nocks. The only non-standard fitting is

the nose assembly fashioned from a modified, dual line sport kite center

T-fitting.

Building notes

The example in the photos shows the excellent work of Pam Kirk and Mike Dennis of Heads Up Kites. Hems

and seams are quite narrow at around 0.25 inch (6 mm). The original

kites were made with single and double-row straight stitching, simple

lap seams and single-folded hems. Zigzags should suffice for the

homebuilder with a standard machine. Since the original plans are in

inches, I'll keep them that way for simplicity, and seam and hem

allowances are shown where needed. Edges marked “cut line” have no

allowances, and dotted lines represent stitches.

|

|

|

Rear of nose

The nose fitting drilled to accept a .125” carbon

rod. This holds a ferrule bent to the angle of the leading edge spars.

Velcro serves to fasten the Dacron flaps that allow easier disassembly.

Icarex PC covers the white flaps in the photo |

|

Rear of leading

edge

A standard APA sport kite leading

edge fitting and c-clip hold the .180” pultruded carbon vertical spar.

The Dacron-reinforced oval hole allows disassembly by sliding spar from

nose fitting. The vertical spars all arch away from the sail, leaving it

flat.

|

|

|

Rear of leading

edge

This is one of the upper bridle points that are

through a slot to allow movement of the SkyShark 3PT leading edge spar.

|

|

Rear of wingtip

Tiny folded strips of Dacron form

loops to tie tensioning lines for LE and leech lines. 75 pound Braided

Dacron line is used for all tension lines.

The FSD nocks have a side notch to

tie to. The leech line goes through the nock, back to the wingtip loop

and back to the nock to be tensioned and tied.

|

|

|

Looking

down the center front

The

.180” carbon keel spar is shown as it supports the keel. At its lower

end a .098 carbon rod is spliced to form the curve of the lower keel.

|

|

Center of

trailing edge

The intersection of the keel and

trailing edge is shown here. The black circular reinforcements are of

pressure sensitive ¾ ounce rip-stop tape applied prior to stitching.

|

|

|

The lower end of

wing vertical spar

Here again the leech lines run through the nock, and

lower trick line and bridles lines attach to the wing spar nocks. |

|

The lower tip of

the keel

This is the connector at the keel tip where the

rear spar joins it at about 60 degrees.

The rear spar on the bottom has a sleeve to stop

it against the fitting, The fitting is actually a T-fitting for

drip irrigation tubing with two barbs removed. This could be

accomplished with .098 leading edge fittings such as those used on the

Prism Micron.

The lanyard to the fitting tensions the fabric.

|

|

|

|

|

The bridle tow points can be made

with adjustable knots for lateral adjustment if desired.

|

|

Leading edge spars

(2) SkyShark 3PT 38.5" long

Wing vertical spar (2)

.180 carbon tubing 25.9 long

Upper keel

spar

(1) .180 carbon tubing 17" long

Lower keel

rod

(1) .098 carbon rod 17" exposed below upper keel spar

Rear center

rod

(1) .125 solid carbon rod 31.25" long

|

|

Apocalypse plan downloads

|

|

The template drawings are

downloadable in a zipped file that includes full-scale CDR, AI and DXF

drawing files.

Download

the drawing files

|

Template drawings are also

downloadable in a full-scale JPG file for builders without a drawing

program.

Download

the JPG file

|

| A JPG file showing an assembled

kite is available.

Download

this assembly file |

Feel free to ask questions. I

haven't made one yet, but plan to.

-Stan |